Westerbeke Notes

Warren Elliott

11/27/2004

Hull #: 44

A few notes for those of us with the Westerbeke 42B.

Raw Water Pump.

First, there is a new raw water pump, P/N 48080, which is a bit larger but directly replaces the old one, P/N 033636. From our Sailnet discussion group, here’s an email from one captain who went through the exchange: “The seals started to leak on my seawater pump so ordered a new one. Found out Westerbeke had replaced it with larger model. The frame and bolt holes match but the pump is larger, has a higher volume, and the impellers are not interchangeable. Just finished mounting the new one. Keep the 45-degree elbow on the inlet. The new pump comes with the 90 degree fitting on the outlet but not the 45. Everything fit and it works fine. Having the old one rebuilt for a spare. Don’t forget to close the seacock before you start this project.

Regards, Steve [Dublin] C-380 #84 Caretta”

Per Westerbeke, some repair parts and repair kits [P/N 034466] for the old unit are still available. Note that a new “kit” version of the new pump is P/N 37431, which also includes a mounting gasket and fittings. The repair kit for the new pump is P/N 49000.

Fuel Filter

For the primary fuel filter, most [all?] of us have a Racor 500 series water separator type. Many of our boats, including mine, came with 2-micron filter elements installed, and we replaced them, as needed, with the same filter size [10 and 30-micron are also available]. The 2-micron units are identified by their hard-to-see part numbers embossed on one end [2010SM-OR] and, more easily, by their brown color.

Westerbeke had been reviewing the filter’s specifications and fuel requirements, and revised their recommendation to 10-micron filtering. Apparently they had discovered some tendency for fuel pumps to fail due to excessive pressure drop in the fuel filters, which increases the suction on their pumps, thus reducing output pressure. Because the engine fuel particulates can be much significantly larger for proper operation, they are now [starting over a year ago] recommending use of a 10-micron filter [note that the secondary filter, built onto the engine, uses a 25-micron element].

The 10-micron replacement element is Racor P/N 2010TM-OR, and is noted by it’s blue color. West Marine’s P/N is 465674.

Circuit Breaker

A few captains have found their 42B’s inoperative, eventually tracing it to a tripped circuit breaker on the engine. This is the main 20-amp breaker, located on a vertical bracket, just aft and to starboard of the middle of the engine. Looking from the engine’s front, it’s just behind the air intake silencer [black] on the left top. The breaker’s reset button protrudes through that vertical bracket.

The circuit breaker’s purpose is to protect engine from short circuits, which obviously might damage wiring, other components, or even your boat. So by-passing or eliminating it is not the answer to an occasional trip of the breaker.

So why do a few 42B’s exhibit occasional circuit breaker tripping, without any apparent real fault? There was some concern that perhaps the nominal current was too near the 20 amp limit. I checked with Westerbeke on this and here is their reply:

“The typical engine running, amperage that will be seen through the breaker is about 4 to 5 amps if you are using a manual shut off cable. If the engine has an electric shut off the amperage will be 5 or so amps more. [Note–we have manual shut-off].

Please note that this breaker is a thermal switch [Note-it’s sensitive to both the heat generated by high currents and by high ambient temps–Warren]. It is characteristic of this type of switch to trip more frequently as it gets older if in fact it has been tripped due to an over current condition a couple of times. The switch is also susceptible to tripping if the engine compartment is hot. This is especially true after the engine has been shut down and it dissipates it’s heat. Often times folks will find this breaker tripped when re starting the unit after it has been sitting for a while. If so it is possible that it tripped after shut down.”

While few have any problem with the circuit breaker, it seems more likely to inadvertently trip for those operating in hot weather, with a relatively long engine run, when the engine compartment becomes very hot. Then, when the engine is shut down and cooling water no longer flows, engine and compartment temperature will tend to rise even higher as the engine dissipates it’s heat.

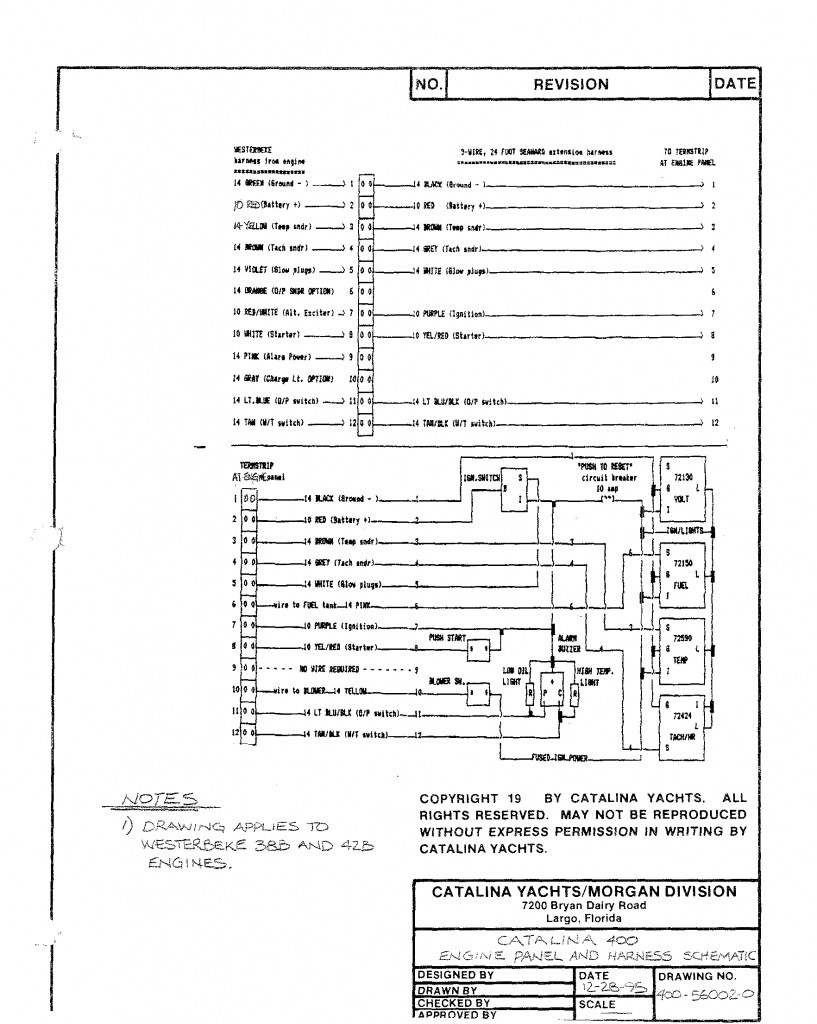

The most obvious suggestion for these type of circumstances is to run the engine compartment blower as long as necessary. This should significantly reduce engine compartment temperature. Unfortunately, the blower switch, which is located on our engine control panel, is not set up to operate with the ignition switch off—which may be just when we need it most. But it’s an easy mod to change the blower switch for anytime operation: simply move the hot side to the red +12V wire [make sure your main power/engine switch is off while making the change]. And, of course, you’ll now be subject to possibly leaving it on too long, running down the battery. So, either be extra careful [ask your admiral to remind you], or be extra fancy and add it a timer.

By the way, this mod could be helpful to all in very hot climes, providing some engine compartment cooling and therefore reducing heat added to the boat.

For those who feel they may have a real circuit breaker problem, Westerbeke’s P/N is 024683. Before ordering or changing the part however, I advise checking the circuit to determine if there is the nominal 4 – 5 amps flowing. If it’s significantly higher, locate and fix that problem–and do it soon as this sort of condition suggests a more serious issue is just around the corner.– Warren